Some time back Ross Reichman of Einhorn LLC and I had been chatting about round knives, head knives and such. Ross is a very talented knife maker. Since he wants to make and market handmade custom leather knives he offered to make one to my suggestions and send it to me for review and testing. A few days ago I received it and have to say that it’s even better than I expected it to be.

Here are some details on the knife:

- Steel: O-1 Tool steel 1/8 inch thick hollow ground blade

- Handle: Walnut finished with Tung oil or also called China wood oil

- Secondary bevel to point to make it sharp

- Heat treated to 62 on the RC scale

- Handle is 3 inch long, 1 1/2 inch on the widest point and 3/4 inch thick on the thickest point

- 1 inch diameter hole within the blade

- 4 inch from tip to “tip”

- 6 inch overall length

Ross asked me to give him my dead honest opinion on this knife and suggest what could be improved as well as letting him know what is good as is. So here goes.

The knife came out the box sharper than a razor-blade. If you tend to cut yourself with your current round knife, handle this one with extreme caution cause you won’t have to worry about band-aids, but pay a visit to the ER and have them stitch your finger back on. Yes, it is that sharp.

With all the following critique, one has to keep in mind that most of this knife making process has been done by hand, just using a jig for sharpening his old man and himself made for this purpose.

Let me take you through one option at a time.

I didn’t want and I don’t need 2 tips on a knife. If my knife goes dull I’ll strop it or sharpen it properly and one can only use one tip at a time. Due to this, this knife has only one real tip. It was important for me that the knife comforts my hand and fits into my palm. I don’t need a long handle. The longer the handle the less control one will have over the cutting edge. This handle fits almost perfect into my hand and I can use the full strength I have in my hand without cramping as I can easily push with my palm. The thumb is resting on the blade and isn’t in the way at all. What I like about that knife is that it has some weight to it. It is 168 grams or 5.92 ounces.

The most important thing about this knife is, is that it cuts. It cuts so extremely well one may have to change his/her way of working. I have been able to skive 1 mm thick lace without any issues at all.

The added hole in the blade is an extra step in the working process, which is well worth the effort. If for whatever reason one has to make a pulling cut instead of pushing this hole saves awkward handling of the knife and allows for a more ergonomic use. Placing the tip of the index or middle finger (I’m using the middle finger and rest the index on the top of the blade, holding it almost like a pen.) will allow to assist in a much easier and comfortable pull than with any other knife on the market. If the fingers are placed correctly, thumb, index and middle finger work in unison to apply adequate pressure to the knife and leather making an excellent cut. If making a pushing cut your palm will do most of the pressure while the thumb is aiding in this. The blade is large enough to have ones index finger resting alongside.

The shape of the handle allows either right or left handed use. Two things could be improved though. The thick end could benefit from a flatter end in a concave shape. This way the handle would comfort the palm even better and causing less pressure points. On the thinner end of the handle, towards the blade the handle should at least be rounded or feathered even. If feathered, the handle could be extended more into the blade area. That however isn’t really necessary.

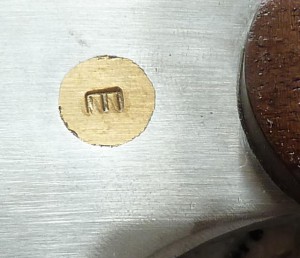

Ross inserted a brass spot into the blade for his Einhorn LLC “E”. The edges of it didn’t turn out nice and the whole blade would have to be sanded down more to address this right. It’s not decreasing the quality of the knife at all, but doesn’t look very nice and dirt will accumulate in these gaps in time. An acid made mark would stand out and if it would carry the name of the owner or a signature of the maker it be very unique.

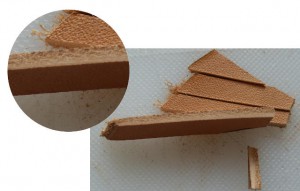

The blade is 1/8″ or 3 mm thick. As much as this contributes to the quality of the knife, there’s a downturn to it as well. It’s limiting the use of the knife. While one can make straight cuts on almost any thickness of leather, curves are limited to about 8 oz. thick leather. This may be possible to be improved with a stronger hollow ground. On the other side one has to understand that certain knives have a certain task and specialty use they have been crafted for. The one knife fits all tasks hasn’t been invented yet.

Before going to market and selling I’m sure Ross will improve the downs of this outstanding knife, that is worth every cent it will cost.

A video will be added later to this post as well, therefore please come back later to watch it. If you would like to provide your thoughts and feedback, please register and let me know what you think.